Wellcraft, V20 and Steplift remain the property of the Wellcraft Company

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looper Shutdown with a rattle noise

- Thread starter nymack66

- Start date

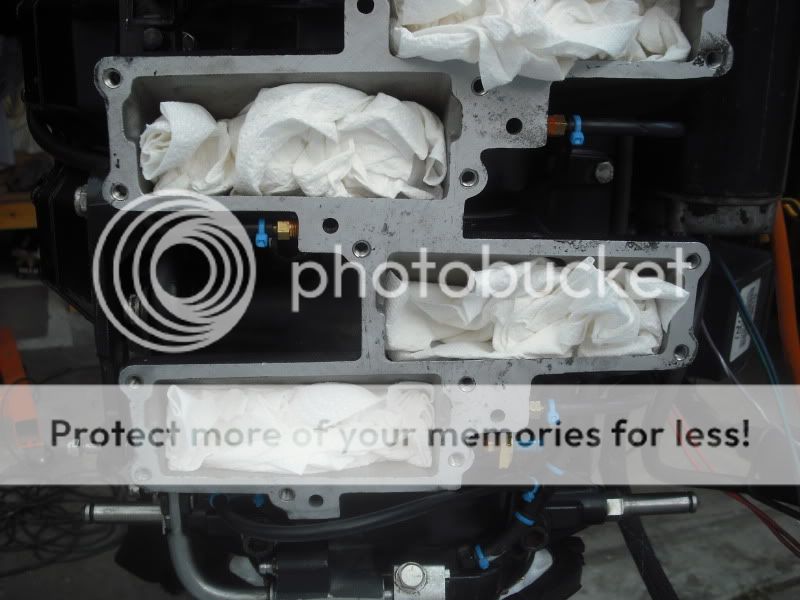

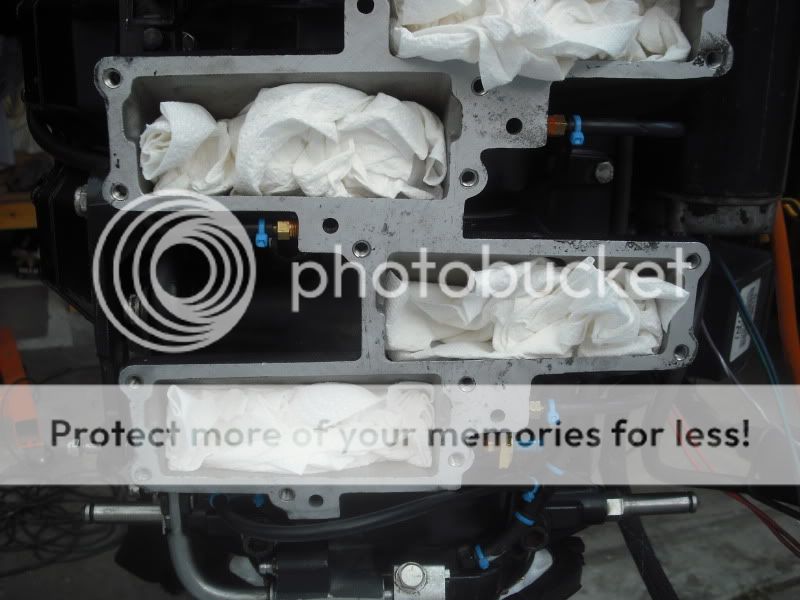

Fuel recirculation Hoses

Can any one please confirmed my recirculation hoses connection ?

Please see the pictures below I simply cannot trust the previous owner at this point for anything.

From the bottom (lower bearing) 1 inch length hose to a T with a check valve connecting up to the Top bearing housing (larger hose)

The little T piece (smaller hose) splits over to the lower intake (cyl 4) and again connected to plain T valve (smaller hose) one side of the T is connected to the check valve on the #4 Cyl the other end of the T connects to nipple on the block #3 Cyl

Number 3 intake connects from check valve directly to #4 Cyl nipple

Number 2 intake connects from check valve directly to #1 Cyl nipple

Number 1 intake connects from check valve directly to #2 Cyl nipple

Reason for me asking the manual shows nothing in regards to the correct connections can some one compare it please ?

Look carefully you can see the blue tie wraps to the check valves

Picture One

Picture 2

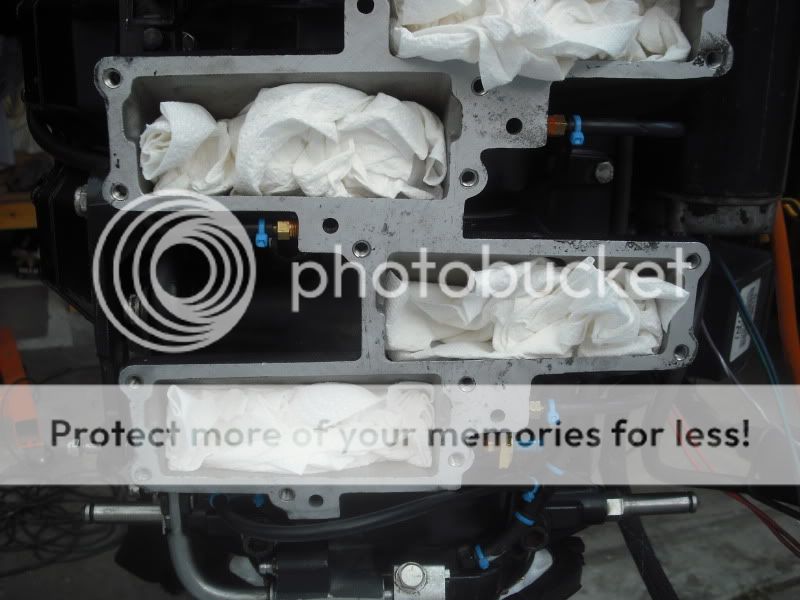

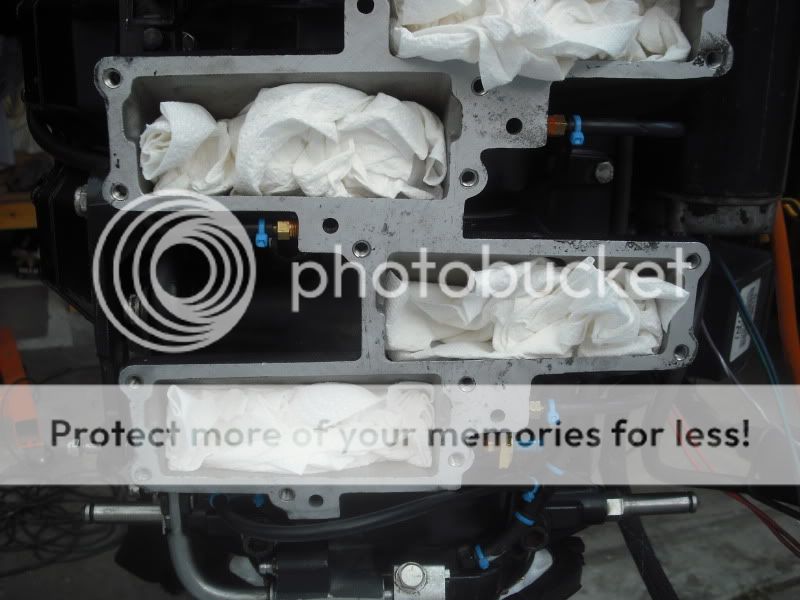

Can any one please confirmed my recirculation hoses connection ?

Please see the pictures below I simply cannot trust the previous owner at this point for anything.

From the bottom (lower bearing) 1 inch length hose to a T with a check valve connecting up to the Top bearing housing (larger hose)

The little T piece (smaller hose) splits over to the lower intake (cyl 4) and again connected to plain T valve (smaller hose) one side of the T is connected to the check valve on the #4 Cyl the other end of the T connects to nipple on the block #3 Cyl

Number 3 intake connects from check valve directly to #4 Cyl nipple

Number 2 intake connects from check valve directly to #1 Cyl nipple

Number 1 intake connects from check valve directly to #2 Cyl nipple

Reason for me asking the manual shows nothing in regards to the correct connections can some one compare it please ?

Look carefully you can see the blue tie wraps to the check valves

Picture One

Picture 2

Anyone ?

I have posted the same questions to the pros on other sites so far no has a clue ! Can any one check his or her engine and let me know please ? I basically is hooking it up back exactly how it was but I am not sure if the previous owner did it correctly ? The Seloc and Evinrude manual does mentioned it and clearly states its importance in regards to lube and proper idle however no diagrams showing the proper hookup.

Thanks

I have posted the same questions to the pros on other sites so far no has a clue ! Can any one check his or her engine and let me know please ? I basically is hooking it up back exactly how it was but I am not sure if the previous owner did it correctly ? The Seloc and Evinrude manual does mentioned it and clearly states its importance in regards to lube and proper idle however no diagrams showing the proper hookup.

Thanks

THEFERMANATOR

God

What you have there looks correct. Make sure and replace that tee in the line that runs from the bottom to the top though, if the check valve goes bad you can starve the upper bearing of oil.

Boyesen Reeds Question

Guys, I fired the motor up in the driveway today , sounds great and starts very easy, problem is she now idles at 3000 RPM with the butterflies completly close and the idle adjustment screw all the way in!

I am currently jetted at .32 for idle and .20 for intermediate

Reason for me asking is Boyesen instructions mentioned on Evinrudes I must reduce the idle jets .5 sizes down and I did not, also I am over jetted currently at .32 hopefully that make sense due to Ferm and I addressing a loading up issue on the old power head which has since blown up and I replace with this new one and I did not downsize on the idle jets

Question is has anyone experience this before? If I reduce the idle jets will this drop my idle rpm's ?

Guys, I fired the motor up in the driveway today , sounds great and starts very easy, problem is she now idles at 3000 RPM with the butterflies completly close and the idle adjustment screw all the way in!

I am currently jetted at .32 for idle and .20 for intermediate

Reason for me asking is Boyesen instructions mentioned on Evinrudes I must reduce the idle jets .5 sizes down and I did not, also I am over jetted currently at .32 hopefully that make sense due to Ferm and I addressing a loading up issue on the old power head which has since blown up and I replace with this new one and I did not downsize on the idle jets

Question is has anyone experience this before? If I reduce the idle jets will this drop my idle rpm's ?

THEFERMANATOR

God

Yes. Chances are it is running pretty lean and will sneeze on you pretty badly when you put it in the water. With the BOYESENS you need to keep it jetted rich as a lean sneeze WILL blow out the BOYESEN reeds(The TDR's don't seem to suffer from this as they are MUCH thicker and made from epoxy). IIRC stock idle jets should be 28's, I would start there and see what she does. Also remember that after break in you will probably need to play with the jets some. I would also swap out your mids for a set of 16's or 14's as the 86 140 carbs were known to be lean in the mid range and would occasionally stall on accel. And run 63's in your mains if the engine was bored.If I reduce the idle jets will this drop my idle rpm's ?

Skools Out

God

what mains do you have 62D? as ferm said get the 63's and you are running double oil right. you need to run double oil for the first 25 to 30 hours and no WOT for more than 40 sec on water until you have about 15 to 20 hours.

Double Oil ? Is this 100:1 ? I ran 40:1 for about an hour now the engine at times will not turn with the starter seems tight ? I can however turn it with my hands and she fired right up. I am afraid the motor is locking up on me so should I increase it to 100:1 the rebuild company told me to use 50:1 , I decided to play it safe and run 40:1. Your thoughts ?what mains do you have 62D? as ferm said get the 63's and you are running double oil right. you need to run double oil for the first 25 to 30 hours and no WOT for more than 40 sec on water until you have about 15 to 20 hours.

THEFERMANATOR

God

25:1 is double oil. I quit double oiling awhile back as I had 2 engines seize up on me from double oiling. Oil burns hotter than gas does and also makes your fuel mixture thicker which causes your engine to lean out under load. It will also cause excess carbon build-up if you don't run some sort of de-carboning additive through the fuel.

25:1 is double oil. I quit double oiling awhile back as I had 2 engines seize up on me from double oiling. Oil burns hotter than gas does and also makes your fuel mixture thicker which causes your engine to lean out under load. It will also cause excess carbon build-up if you don't run some sort of de-carboning additive through the fuel.

Thanks guys, Ferm should I use 40:1 or 25:1 ? I did see some carbon on the plugs from the 40:1 with just under two hours on it ! I am really concerned about the lock up on the engine ?

Skools Out

God

i'd run 25:1 up to you that's what i've run in all the motors i've rebuilt with never a motor issue.

Help !

I install a rebuild power head , during the break 24:1 oil premix , If I run the engine for hours variable throttle the engine runs like it should, shut-off fires right back up , however if I let it sit for 15 to 20 minutes it will not crank period , manually turn the engine my hand tight i can feel it.

Once it cools down from 145 degrees to 120 degrees it fires right up

Question is is this normal ?

I am certainly not overheating since 145 degrees for a block that is just shut-off I have new gauges and senders installed on both starboard and port side of the block , At the time of the shut-off the temp is 130/125 , with the engine off it rises to 135/145 that's when it locks up not even the starter can turn it .

Should I be concerned or this is normal ?

I install a rebuild power head , during the break 24:1 oil premix , If I run the engine for hours variable throttle the engine runs like it should, shut-off fires right back up , however if I let it sit for 15 to 20 minutes it will not crank period , manually turn the engine my hand tight i can feel it.

Once it cools down from 145 degrees to 120 degrees it fires right up

Question is is this normal ?

I am certainly not overheating since 145 degrees for a block that is just shut-off I have new gauges and senders installed on both starboard and port side of the block , At the time of the shut-off the temp is 130/125 , with the engine off it rises to 135/145 that's when it locks up not even the starter can turn it .

Should I be concerned or this is normal ?

THEFERMANATOR

God

I would be concerned. Who did the build? Sounds to me like somebody didn't check the ring end gap and the rings are sticking once shut off. And 145 is not even remotely hot for one of these engines, IIRC it should be running around 150-160 at idle and then drop off to 100-125 above 3000.

I would be concerned. Who did the build? Sounds to me like somebody didn't check the ring end gap and the rings are sticking once shut off. And 145 is not even remotely hot for one of these engines, IIRC it should be running around 150-160 at idle and then drop off to 100-125 above 3000.

Powerhead Exchange in Tampa ..

THEFERMANATOR

God

Powerhead Exchange in Tampa ..

They used to do good work, I used to use them as my machine shop as well. Was it Lou you dealt with or Vaughn? I have had some problems with pistons that I got from them in the past though with em sticking for no apparent reason.

They used to do good work, I used to use them as my machine shop as well. Was it Lou you dealt with or Vaughn? I have had some problems with pistons that I got from them in the past though with em sticking for no apparent reason.

It was Vaughn seems like a real nice guy, But its time like this when one is expose , I left a voice mail for him so far no return call ..