Dana A

Member

Newbie here, Been waiting at the door to get in!

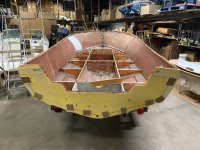

Had my son come home and tell me his friends father had a boat in his back yard that he'll give me. Asked whit it was and he said a 20 ft wellcraft, I told him I would have to take a look at it as I had one a year ago (70's ctr console) that sunk to recover the 150 suzuki 4 stroke on it, that boat and decks transom were a sponge and told them I dont want that boat.

I went and looked at the cuddy my son was offered and decks were solid, transom, questionable. Hull and liner are almost flawless just highly oxidized

Cleaned it out, brought it to the shop and dug deeper and deeper and deeper.

Great winter project for my son and his three pals (all 22 yo) during these trying times, they said were game.

they've been to the shop 5 out of 7 days a week after work doing the work (ok about 2/3 of the work)

Plan is Seacast Stringers and Transom (and every other piece of wood in the hull

Were planning on a 25' transom or option of full transom and bracket

Pics I've seen with brackets they seem to squat with the engine weight further back. would love to hear from someone who has driven both variants

(planning on a 200 yami 2 smoke)

Larger fuel Tank planned, I will say they slapped these boats together.

Fuel tank was foamed in (factory) almost 4 inches off center at an angle where I was able to suck 6 gal of unusable fuel from the tank with the boat level

https://www.youtube.com/watch?v=1xCBOzW9EZ8&feature=youtu.be

Had my son come home and tell me his friends father had a boat in his back yard that he'll give me. Asked whit it was and he said a 20 ft wellcraft, I told him I would have to take a look at it as I had one a year ago (70's ctr console) that sunk to recover the 150 suzuki 4 stroke on it, that boat and decks transom were a sponge and told them I dont want that boat.

I went and looked at the cuddy my son was offered and decks were solid, transom, questionable. Hull and liner are almost flawless just highly oxidized

Cleaned it out, brought it to the shop and dug deeper and deeper and deeper.

Great winter project for my son and his three pals (all 22 yo) during these trying times, they said were game.

they've been to the shop 5 out of 7 days a week after work doing the work (ok about 2/3 of the work)

Plan is Seacast Stringers and Transom (and every other piece of wood in the hull

Were planning on a 25' transom or option of full transom and bracket

Pics I've seen with brackets they seem to squat with the engine weight further back. would love to hear from someone who has driven both variants

(planning on a 200 yami 2 smoke)

Larger fuel Tank planned, I will say they slapped these boats together.

Fuel tank was foamed in (factory) almost 4 inches off center at an angle where I was able to suck 6 gal of unusable fuel from the tank with the boat level

https://www.youtube.com/watch?v=1xCBOzW9EZ8&feature=youtu.be

Attachments

Last edited:

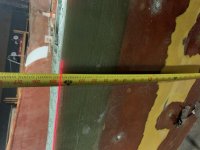

Only comment I will make is about the transom. Most people do not realize that it's curved, not straight across, so they cut away the back glass and leave the interior part of the transom sandwich like you did. (Which is exactly backwards from the way it should be done which is to leave the outside and just cut the inside glass). Damage is done, so no way to change it. Just be careful when building the new transom, try and get it back as close to original as possible.

Only comment I will make is about the transom. Most people do not realize that it's curved, not straight across, so they cut away the back glass and leave the interior part of the transom sandwich like you did. (Which is exactly backwards from the way it should be done which is to leave the outside and just cut the inside glass). Damage is done, so no way to change it. Just be careful when building the new transom, try and get it back as close to original as possible.