bsteckel

Junior Member

i know a lot of you guys have used durabak on the floors of your boat with success. i am getting mine (fisherman 20 center console) ready for paint and was thinking of painting the top of the sides, down the inside sides and also the floor with durabak. the outside is getting painted .. doing the filling and sanding now.

i thought maybe this would be better than painting the top and insides with regualr paint ... if i wack some sinkers off the durabak, no big deal and it is easy to touch up.

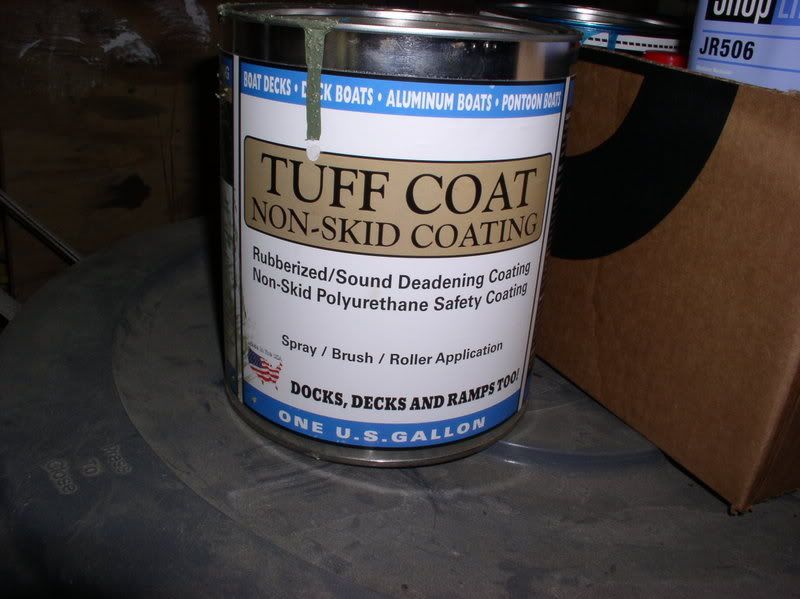

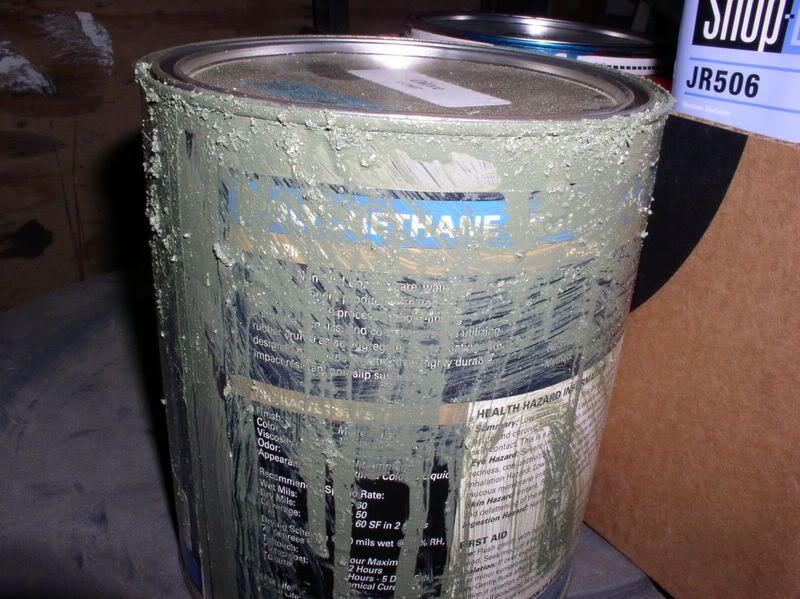

also, anyone use the stuff cabellas sells .. think it is called tuff cote or something ... ? or other brands that may be more cost effective?

also, what would be your guess on how much paint i would need to do this project (floor, sides, and top)?

open to your suggestions ... thanks as always.

Brad

i thought maybe this would be better than painting the top and insides with regualr paint ... if i wack some sinkers off the durabak, no big deal and it is easy to touch up.

also, anyone use the stuff cabellas sells .. think it is called tuff cote or something ... ? or other brands that may be more cost effective?

also, what would be your guess on how much paint i would need to do this project (floor, sides, and top)?

open to your suggestions ... thanks as always.

Brad