Night_Sailor

Member

I priced out a sheet of Nida-Core. 1/2" 4x8 sheet was $261, which was about the price of a pre-made Ebox for my center console. The reason I bought this boat was because it had a T-Top. I want both a hard top and an E-Box to provide shade and a bit more space.

The problem was I didn't like the shape of any of the Ebox's for sale commercially. It turns out the 4x8 sheet is about the right amount of material for an E-Box and a hardtop. Thought it would be good to build the E-Box first.

Nida-Core seems like a good application for this. Rather than build a form and go for a glamorous look, I decided to built it from flat pieces tabbed together and try and keep both projects light.

The one problem I had was the Nida-Core, is it came with a layer of gel-coat. Not what I wanted so I had to grind all that off.

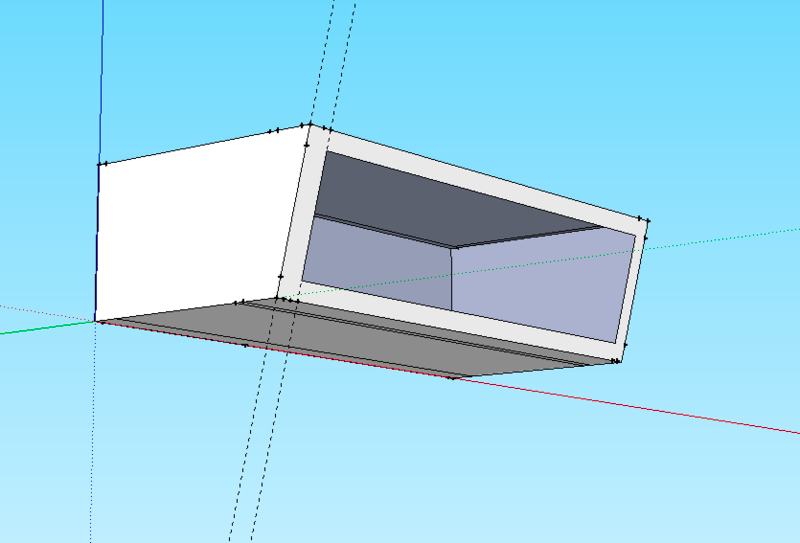

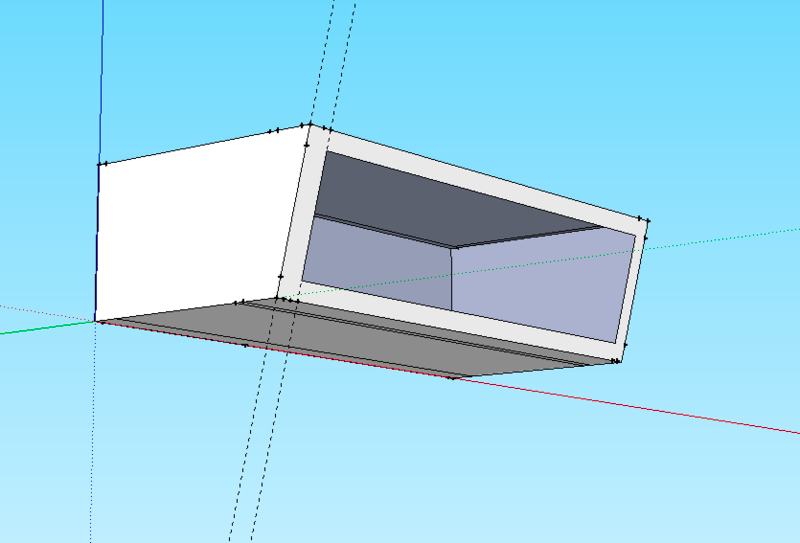

Here is my rough plan:

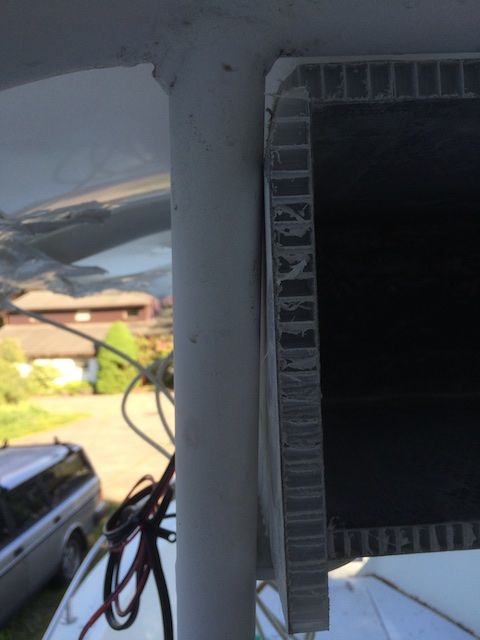

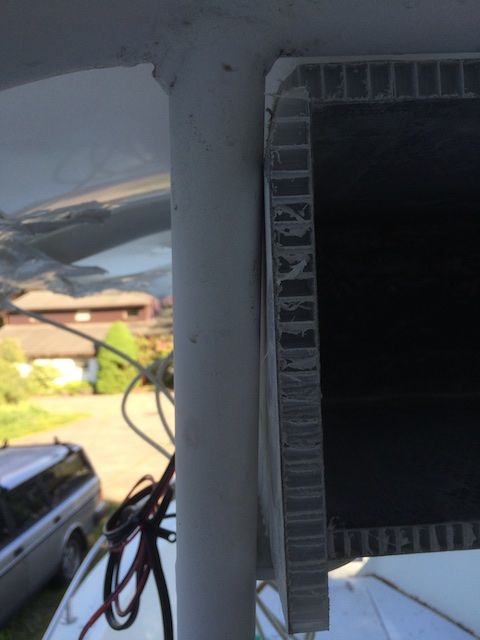

Progress so far. I've tabbed in the inside, and test fit it. I found it was a bit tight at the top, so I shaved off some material. I've since tabbed in most of the exterior--and just have the shaved area, which will need two more sessions--for tomorrow.

Here it is looking in the front. I plan to angle the front face downward slightly. I left both sides square so it would stand up while I worked.

The top edge was a bit tight, so I shaved off both sides. This was my first test fitting. I actually shaved off quite a bit more at the top on both sides to allow room for a couple of layers of fiberglass cloth.

Here it is from the front:

After I finish the sides, I'll cut two holes in the bottom for speakers.

Next, I'll start building a picture frame type faceplate. I also want to build a flush mount for a VHF radio, Stereo, and small chart-plotter/fish-finder. I need to figure out a way to hinge that so I can access it for service.

I also want a Plexiglass cover plate that I can lock closed when not in use and lock up when underway.

I've been doing lots to my center console. New seat cushions, all new wiring, switches, lights and fuse panels, mounted a 6 Amp charger and a Live well pump to glued in plywood panels on the hull to save space. I'm in the middle of installing trim tabs.

The only thing I kept--the courtesy lights. I like they way they look and it came with plenty of spare bulbs.

The problem was I didn't like the shape of any of the Ebox's for sale commercially. It turns out the 4x8 sheet is about the right amount of material for an E-Box and a hardtop. Thought it would be good to build the E-Box first.

Nida-Core seems like a good application for this. Rather than build a form and go for a glamorous look, I decided to built it from flat pieces tabbed together and try and keep both projects light.

The one problem I had was the Nida-Core, is it came with a layer of gel-coat. Not what I wanted so I had to grind all that off.

Here is my rough plan:

Progress so far. I've tabbed in the inside, and test fit it. I found it was a bit tight at the top, so I shaved off some material. I've since tabbed in most of the exterior--and just have the shaved area, which will need two more sessions--for tomorrow.

Here it is looking in the front. I plan to angle the front face downward slightly. I left both sides square so it would stand up while I worked.

The top edge was a bit tight, so I shaved off both sides. This was my first test fitting. I actually shaved off quite a bit more at the top on both sides to allow room for a couple of layers of fiberglass cloth.

Here it is from the front:

After I finish the sides, I'll cut two holes in the bottom for speakers.

Next, I'll start building a picture frame type faceplate. I also want to build a flush mount for a VHF radio, Stereo, and small chart-plotter/fish-finder. I need to figure out a way to hinge that so I can access it for service.

I also want a Plexiglass cover plate that I can lock closed when not in use and lock up when underway.

I've been doing lots to my center console. New seat cushions, all new wiring, switches, lights and fuse panels, mounted a 6 Amp charger and a Live well pump to glued in plywood panels on the hull to save space. I'm in the middle of installing trim tabs.

The only thing I kept--the courtesy lights. I like they way they look and it came with plenty of spare bulbs.